Contact Us | 1.800.2.BERLIN

Berlin Packaging Dominates NACD Awards with Record-Breaking 15 Award Victories

Results further proof of global packaging juggernaut’s commitment and dedication to its customers’ success

The bar has been raised by Berlin Packaging, the world’s largest supplier of glass, plastic, and metal containers and closures, with the biggest awards haul of any company in recent National Association of Container Distributor (NACD) history. Berlin Packaging was awarded an unprecedented 15 medals during the NACD 2019 packaging awards competition, celebrating the most innovative packaging design from the past year. Including these latest award victories, Berlin Packaging now boasts more than 50 total NACD awards received over the past six years.

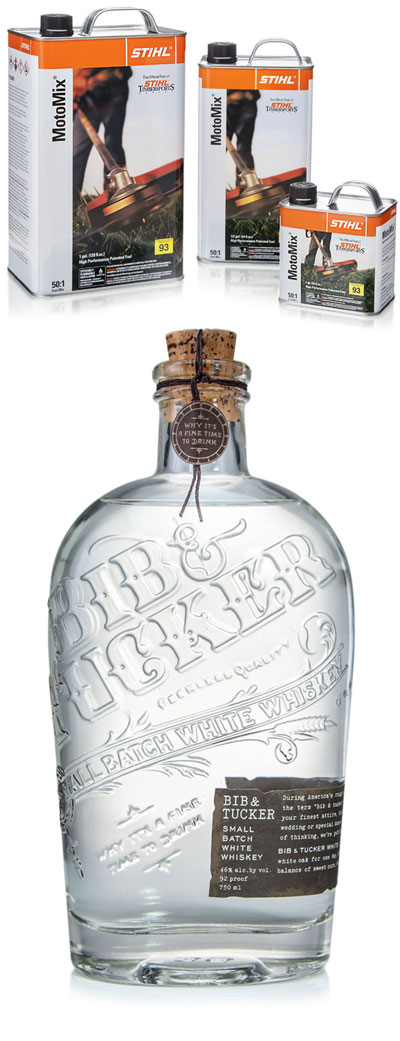

The $2.6 billion packaging juggernaut’s 15 awards spanned eight categories, including sweeps of two highly competitive categories – Beverage and Household Goods. In total, nine of these wins were attributed to projects with the company’s world-class design and innovation division, Studio One Eleven, which offers structural package design and branding services at no-charge in exchange for packaging business. Additionally, Berlin Packaging flexed its international muscle with winning projects from Italy and England, two of the company’s 100+ global sales and warehouse locations.

Beyond accolades, company’s mission is to grow customers bottom lines

While honored by the awards, Berlin Packaging measures it’s success by how it helps clients increase sales, reduce costs and improve productivity. To achieve this, Berlin customers benefit from the company’s network of 900+ manufacturing partners, plus a robust selection of value-added offerings, including warehousing and inventory management programs, global sourcing, and much more.

“Our number one priority is to thrill our customers, and the continued recognition we receive year after year from the NACD validates our unique business model,” said Andrew Berlin, Chairman and CEO of Berlin Packaging. “From the world class capabilities of our Studio One Eleven design and innovation division, to the proactive advocacy of our Quality team, to our below market financing for capital expenditures, we offer a multitude of income-boosting services at no-charge to our customers to help them package more profit,” added Berlin.

Multiple Category Wins including People’s Choice Award

Receiving the coveted People’s Choice Award was the Heaven’s Door Whiskey bottle, a Studio One Eleven project that helped translate Bob Dylan’s vision for standout packaging for his premium spirits. The bottle also took home the bronze medal as part of Berlin’s Beverage category sweep. The gold medal in Beverage was won by Studio One Eleven’s custom guitar-inspired design of Pickers Vodka, while the uniquely-colored glass bottle with copper debossed bar top stopper of Bullards Gin, won silver, in addition to a bronze in the Best Use of Custom category.

Berlin also swept the Household category, led by the revolutionary twin-chambered, one-sprayer design of the Rejuvenate Dual System Outdoor House Wash and Window Cleaner. The newly engineered Morton Pool Salt won silver and Febreeze PLUG earned bronze.

Other Berlin Packaging winners include:

Ecolab Sprayer – Gold – Industrial

Morton Kosher Salt – Gold –Food

Sabino Basso Olive Oil – Silver – Food

ASEA Via Line – Silver – Nutraceuticals

Alterna Caviar – Silver – Personal Care

Zep High-Output Chemical Sprayer – Bronze – Industrial

Poo-Pourri – Bronze – Novelty

For additional information on Berlin Packaging, including its full list of income-boosting services, visit BerlinPackaging.com.